Ventilation

To improve energy efficiency, modern buildings are constructed to be more airtight. However, this limits the natural air exchange with the outside. As a result, there is often not enough natural ventilation to maintain an optimal indoor air quality for the occupants. That’s why controlled, mechanical ventilation has become essential in well-insulated buildings.

Demand-Controlled Ventilation

Modern ventilation systems regulate the indoor air quality by monitoring different parameters, such as temperature, relative humidity, carbon dioxide (CO2), total volatile organic compounds (TVOC) and carbon monoxide (CO).

These factors fluctuate depending on the number of people in a room, the time spent inside, outdoor weather conditions, and the presence of certain indoor pollutants. Most ventilation systems are designed to supply sufficient fresh air, even when spaces are fully occupied. When rooms are empty or only lightly used, airflow can be reduced while still maintaining sufficient air quality. Continuously circulating fresh air helps to remove indoor airborne contaminants — including viruses — by flushing them out through ventilation ducts, preventing them from accumulating indoors.

In offices and workspaces, air quality sensors integrated into heating, ventilation, and air conditioning (HVAC) systems maximise energy efficiency and enable proper ventilation and good air quality, ensuring a healthy and productive work environment. However, there is a downside to ventilation: increased energy consumption and higher costs, which contribute to greenhouse gas emissions and ultimately to climate change.

Each year, significant amounts of energy and money are wasted due to inefficient heating, ventilation, and air conditioning practices — with open windows being a major cause. Malfunctioning HVAC systems can also worsen indoor air quality instead of improving it. Finding the right balance between maintaining high indoor air quality and minimising energy losses remains a key challenge.

85% of buildings in the EU were built before 2000 and amongst those 75% have a poor energy performance

Temperature and relative humidity (RH)

Temperature and relative humidity (RH) are two basic parameters that determine the comfort and well-being of residents. In this respect, it is not the absolute temperature, but especially the apparent temperature that is important – the temperature humans actually feel. This temperature can deviate substantially from the absolute temperature due to various factors, including humidity, wind speed – or drafts when indoors – and exposure to sunlight. Furthermore, it depends on the individuals occupying the room and the activities they perform.

Indoors, the apparent and absolute temperature will mostly differ based on the

interplay between

relative humidity and temperature. Higher relative humidity enhances the effects

of

heat and

cold. Cold air combined with high relative humidity levels feels chilly, while

warm

air combined

with a high relative humidity feels warmer than drier warm air.

Therefore, ventilation in function of temperature and relative humidity level is

especially

interesting in rooms where large fluctuations of these two parameters regularly

occur, such as

in the kitchen or bathroom.

Most Sentera sensors can measure both ambient temperature and relative humidity.

Free cooling during the night

Generally, in summer, there is a demand to bring the indoor temperature down, and in winter,

there is a demand to raise the indoor temperature and limit heat losses. Heat exchangers can

help with this, as do fan heaters.

The most important application of ventilation in function of temperature is free cooling,

which

is an alternative or supplement to air conditioning. As outside temperatures lower during

the

night, the ventilation system starts sucking the cooler air inside. Over time the building

starts to cool. When the building has reached the desired temperature, the system stops

supplying air inside. It is cost-effective and the outside air will benefit the indoor air

quality.

What are good indoor air temperature levels?

The ideal temperature of an indoor environment also depends on its use. Generally, there are four categories of work environments requiring different temperature levels:

HEAVY WORK: 13 °C

For heavy physical labour, cooler temperatures of around 12–14 °C are recommended to prevent overheating.

LIGHT WORK: 16 °C

Light physical activity usually requires a slightly warmer environment, often in the 16–18 °C range.

SHOPS AND HOSPITALS: 18 °C

Public spaces like shops and hospitals are often kept around 18–20 °C for comfort and health reasons.

OFFICES: 20 °C

Offices typically have recommended temperatures between 20–22 °C to ensure comfort for mostly sedentary work.

Carbon dioxide (CO2)

Carbon dioxide (CO2) is a natural by-product of both metabolic processes in living organisms and combustion. Chemically, it consists of one carbon atom and two oxygen atoms. Humans produce CO2 as they breathe, which makes it a common indoor air pollutant, especially in crowded or poorly ventilated spaces. Although CO2 is a normal component of the air we exhale, high levels can be harmful. Moderate concentrations may lead to headaches and fatigue, while higher levels can cause nausea, dizziness, and even vomiting. In extreme cases, very high concentrations of CO2 can lead to loss of consciousness.

Indicator of occupancy and air quality

Carbon dioxide is a reliable indicator of how many people are present in a room. Since most indoor CO2 comes from human metabolism, its concentration is closely linked to how intensively a space is being used. To maintain healthy indoor air quality and prevent CO2 build-up, it is important to ensure a constant supply of fresh air through proper ventilation. Monitoring CO2 levels is therefore important because high concentrations can indicate poor air quality. When CO2 levels rise, it often means that fresh air is running low and other pollutants – such as volatile organic compounds (VOCs) and airborne pathogens – may also be accumulating.

Modern demand-controlled ventilation systems use CO2 sensors to assess whether additional fresh air is needed in a space. These systems automatically adjust ventilation based on real-time CO2 levels, ensuring optimal air quality that matches the number of occupants and their activity level. CO2-controlled ventilation is especially useful in areas with variable occupancy, such as meeting rooms, classrooms, and university lecture halls. Sentera offers a wide range of reliable CO2 sensors that can be integrated into these systems, making them a smart choice for effective and energy-efficient indoor climate control.

When an ill person uses a room, infectious airborne particles will be released, linger and accumulate – especially in poorly ventilated spaces. Although it is not feasible to measure all types of infectious particles directly, CO2 serves as a useful indicator. Higher CO2 levels often correlate with a higher risk of airborne disease transmission. By using CO2-based demand-controlled ventilation, the spread of disease from asymptomatic or pre-symptomatic individuals can be significantly reduced, as fresh air dilutes potentially harmful particles more effectively.

What are recommended CO2 levels?

Sentera CO2 sensors have adjustable detection ranges to suit various applications. For typical indoor environments, it is recommended to keep CO2 concentrations below 800 ppm to maintain good air quality. Levels should not be forced below 400 ppm, as this is the average concentration of outdoor air. In specialised environments like greenhouses, however, higher CO2 levels are often desired to promote plant growth.

Total volatile organic compounds

Volatile organic compounds (VOCs) are organic chemicals that easily evaporate at room temperature. They are a major contributor to air pollution at ground level and a common concern in indoor environments. Total VOC or TVOC refers to the combined concentration of multiple VOCs simultaneously present in the air.

Health and comfort effects

Exposure to VOCs can cause eye, nose, and throat irritation, headaches, dizziness, fatigue, and difficulty concentrating. Long-term exposure, particularly to compounds like formaldehyde, has been linked to cancer and the development of allergies in children. Beyond health, VOCs also affect comfort. Some VOCs, such as toluene, are irritating. High VOC levels, such as those caused by detergents, can negatively affect the perception of cleanliness and release bad odours.

Volatile organic compounds are always present to some degree, both indoors and outdoors. However, indoor concentrations are typically 2 to 5 times higher, and in some cases even up to 1000 times higher, depending on the activity and materials used in the space. New buildings — especially those less than two years old — often have the highest VOC levels due to emissions from construction materials and finishes. Indoor and outdoor sources from VOCs are humans, cleaning agents, paints, pesticides, industrial pollution, etc.

On the other hand, as we mentioned before, different room types have different VOC profiles:

- Kitchen and bathroom: cooking, cleaning products

- Living room, bedroom, and office: building materials, furniture, carpets, cleaning products, and human (and animal) presence

- Garage and storage room: exhaust fumes, automotive fluids, paints and pesticides

In this respect, hospitals and nursing homes are especially prone to high VOC levels due to frequent use of disinfectants and cleaning agents.

Ventilation based on TVOC level: smart and efficient

Ventilation in function of TVOC level is interesting in environments where indoor air quality needs to be optimised on a continuous base, such as living rooms, office buildings, certain industrial environments, etc. Modern ventilation systems use TVOC sensors to monitor air quality and adjust airflow in real time. These sensors are sensitive to hydrogen (H2), which is emitted by humans along with CO2 during respiration. Because human presence correlates with increases in both gases, this method allows the system to:

- Detect occupancy levels

- Differentiate between human-sourced and material-sourced pollutants

- Optimise ventilation based on actual air quality needs

This demand-controlled ventilation improves air quality, enhances comfort, and reduces energy consumption by ventilating only when necessary.

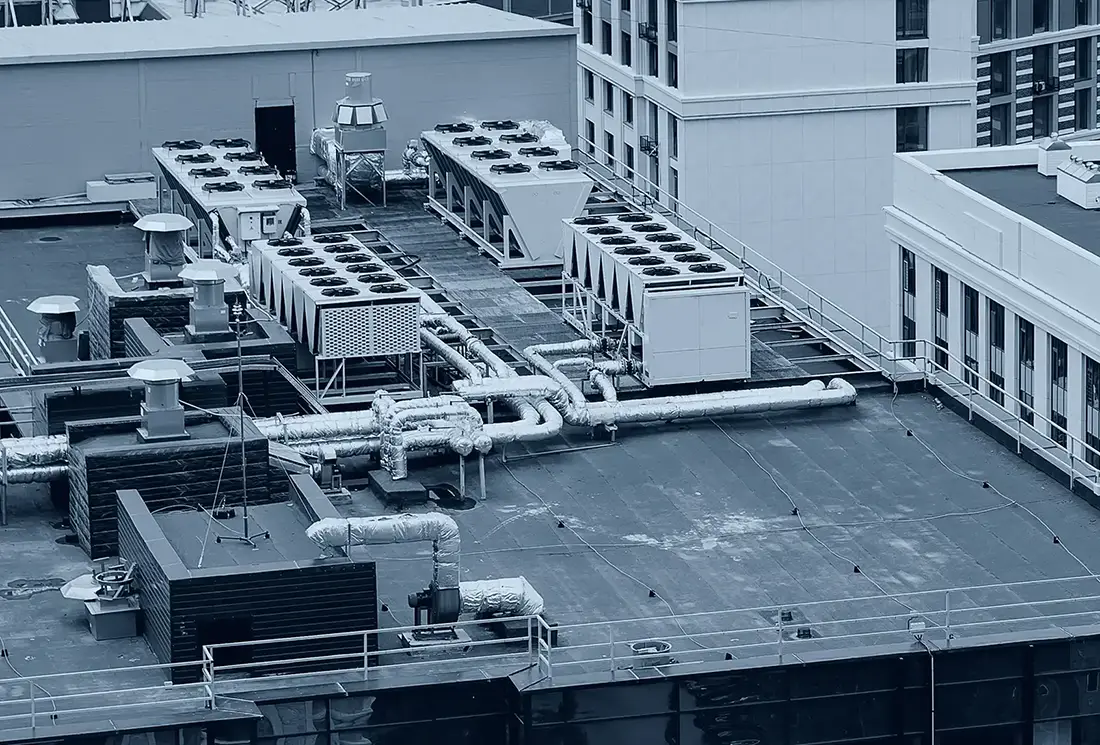

Differential Pressure

The term differential pressure refers to the difference in air pressure between two distinct points in a system. Maintaining the correct differential pressure is crucial for proper airflow, indoor air quality, and energy efficiency.

Differential pressure devices, including switches, sensors, and controllers, play a key role in ventilation systems, especially in heating, ventilation, and air conditioning (HVAC) and controlled environments like cleanrooms, labs, and hospitals. They facilitate the efficient and cost-effective operation of the systems by monitoring and regulating airflow and detecting clogged filters. In short, differential pressure devices are key to creating safer, smarter, and sustainable indoor environments.

Insufficient pressure differentials can lead to issues such as inadequate airflow, which compromises indoor air quality and comfort. Conversely, excessive differentials may strain components and increase energy consumption.

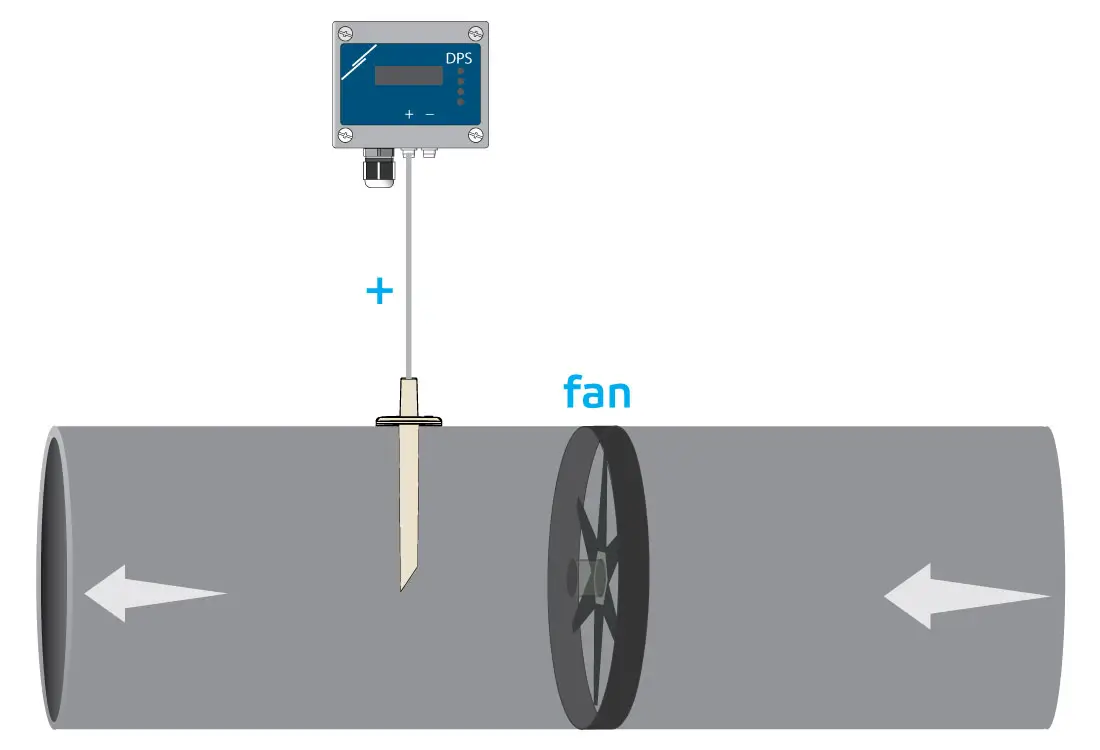

Differential pressure devices

Sentera’s differential pressure sensors, switches and controllers are used to measure and control low differential pressures of non-aggressive and non-combustible gases, but they have been especially developed for air.

-

Differential pressure switch

Detects pressure differences between two points and activates/deactivates a circuit based on a predefined threshold. When the pressure difference exceeds or falls below a set point, the switch either opens or closes the electrical circuit, triggering an alarm or action. -

Differential pressure sensor

Measures and provides real-time data on the pressure difference between two points.

Uses various technologies (e.g., piezoresistive, capacitive) to measure the difference in pressure and converts it into an electrical signal (usually analogue). -

Differential pressure controller

Actively maintains a setpoint for pressure difference. Uses a PI (Proportional-Integral) algorithm to adjust the output (e.g., a 0-10V signal) to ensure the pressure difference stays at the desired value.

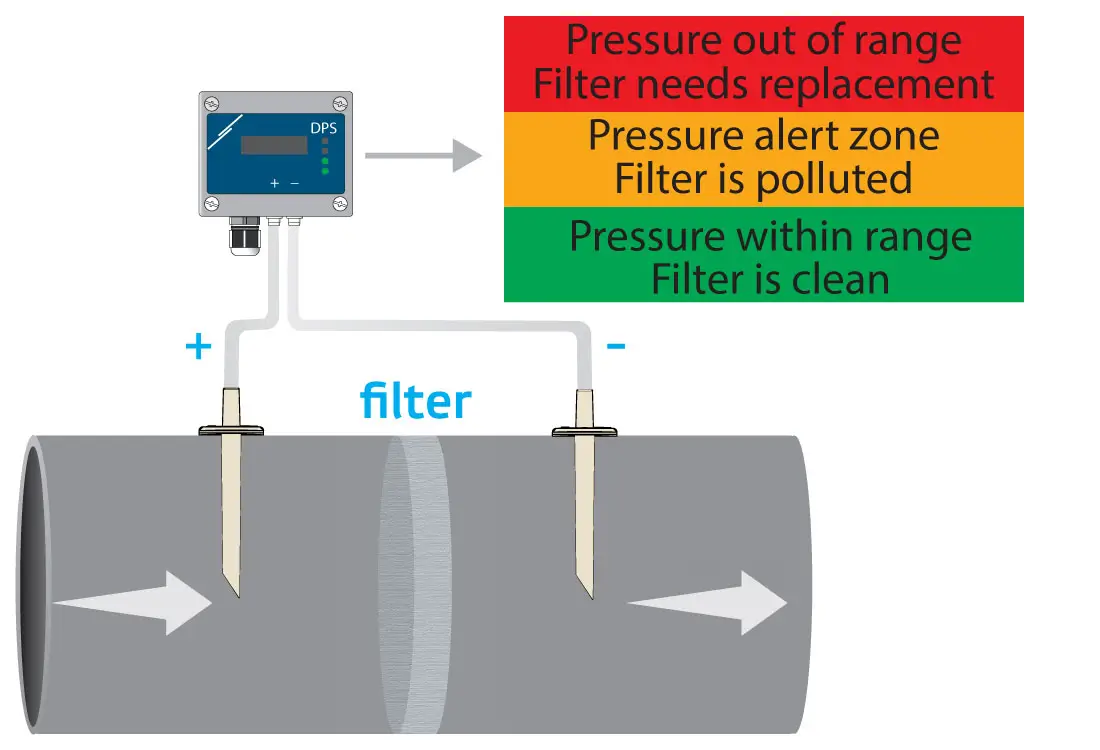

Air filter monitoring

One major application of differential pressure is filter monitoring. An air filter monitoring device is a piece of equipment used in HVAC systems to monitor the condition and efficiency of air filters. The device can indicate when filters need replacement or maintenance. As air filters become dirty, the pressure drop across the filter increases. Differential pressure sensors detect this change and can trigger alerts. This ensures clean air supply, improves energy efficiency, and extends system life.

Sensors and controllers are indispensable to optimise your ventilation system. Measure or control differential pressure (Pa), airflow velocity (m/s) or airflow volume (m³/hr). Make sure that the correct amount of fresh air is supplied into your building and detect clogged filters to ensure the inhabitants’ comfort and optimal indoor air quality.