Special Applications

Each environment poses its own climate challenges. Ensuring good – and above all safe – air quality in car parks, creating healthy living conditions for animals in barns, or achieving the ideal setting for plant growth in greenhouses: specific climates require a targeted approach! In this “Special Applications” section, we highlight solutions tailored to unique, yet common, climate conditions.

Car Parks

Underground parking garages form a particular challenge to ventilation systems. To protect both garage users and building occupants, a continuous monitoring is crucial. Smart ventilation systems use CO and CO2 sensors to detect poor air quality and activate ventilation before concentrations reach dangerous levels.

Barn Climate

An optimal barn climate is essential in modern livestock farming for animal health, welfare, behaviour, and productivity. It also plays a significant role in the safety and comfort of the farmer and the protection of the environment. Climate control in barns involves several aspects, including ventilation, heating, and lighting.

Greenhouse

Greenhouses play a vital role in modern agriculture by creating a protected and controlled environment for plant growth. A critical aspect of greenhouse management is climate control. Maintaining the right temperature, humidity, and air composition directly influences crop quality, growth rates, and overall yield.

Car Parks

Underground parking garages form a particular challenge to ventilation systems. These car parks are enclosed spaces with typically low ceilings where toxic exhaust gases from vehicles can quickly accumulate, posing serious health risks. To protect both garage users and building occupants, a continuous monitoring is crucial. Smart ventilation systems use CO and CO2 sensors to detect poor air quality and activate ventilation before concentrations reach dangerous levels.

Garage gases

In general, cars with combustion engines primarily emit carbon dioxide (CO2) and carbon monoxide (CO) as exhaust gases. The relative amount of each gas can vary depending on several factors including the type of fuel, engine efficiency, and driving conditions. Typically, the emission of CO2 is much higher than the emission of CO. This is because CO2 is a by-product of the complete combustion of hydrocarbon fuels such as gasoline or diesel, while CO is produced when incomplete combustion occurs.

Liquefied Petroleum Gas or LPG is commonly used as a fuel for vehicles and as a heating source. In underground parking garages, there's a risk of leaks from vehicles or from the storage systems themselves. LPG is highly flammable, and in the confined space of an underground parking garage, any leakage can pose a significant fire hazard. Vehicles with an LPG tank are therefore not allowed in all parking garages. Measuring LPG levels helps to detect any leaks promptly and to enable the monitoring of potentially dangerous concentrations.

Carbon dioxide (CO2)

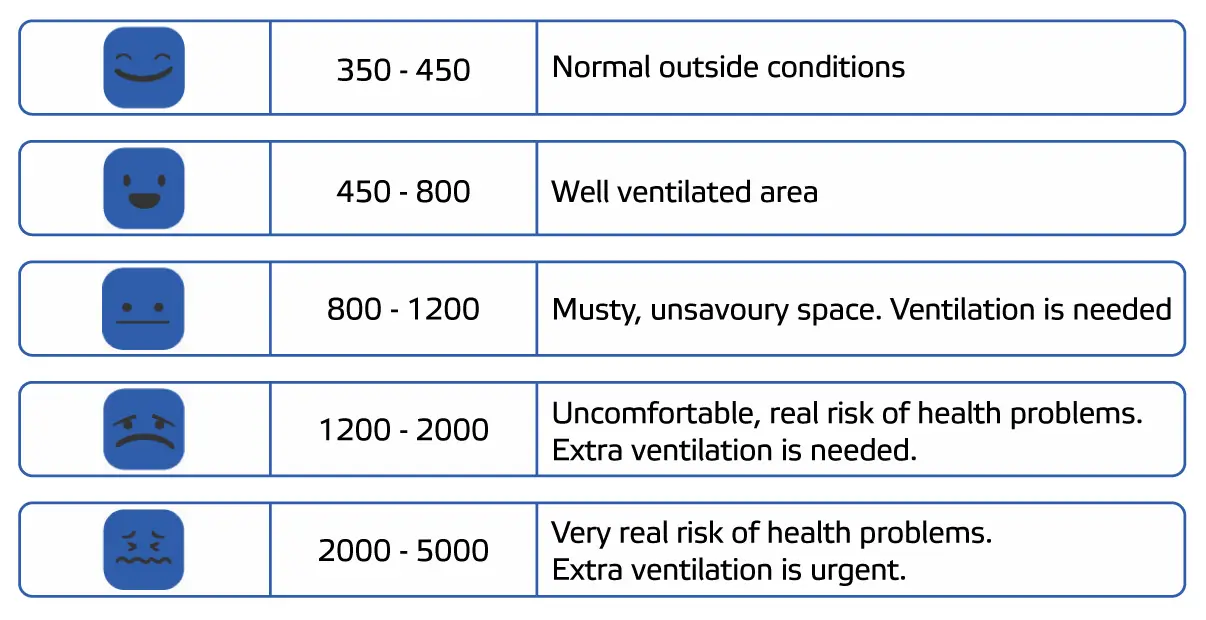

Carbon dioxide (CO2) is a naturally occurring greenhouse gas and is – in small amounts – essential for life on earth. However, in enclosed spaces, CO2 levels can rise due to a combination of outdoor air, human respiration, and insufficient ventilation. Moderate to high CO2 levels can cause headaches, reduced concentration and fatigue. At higher concentrations, symptoms may include nausea, dizziness and vomiting. In extreme cases, loss of consciousness can occur. Indoor CO2 levels between 400–1000 ppm are considered acceptable. Values above 1000 ppm indicate poor ventilation and fresh air needs to be supplied to remove excess CO2.

In the presence of sufficient oxygen, the main by-products during fuel combustion in an engine are CO2 and water vapour (H2O). Consequently, the amount of CO2 released during combustion is generally higher than the amount of carbon monoxide (CO). Modern engines are designed to optimise the combustion process to produce as much CO2 as possible through complete combustion while minimising the production of carbon monoxide (CO) and other harmful emissions.

Carbon monoxide (CO), the silent killer

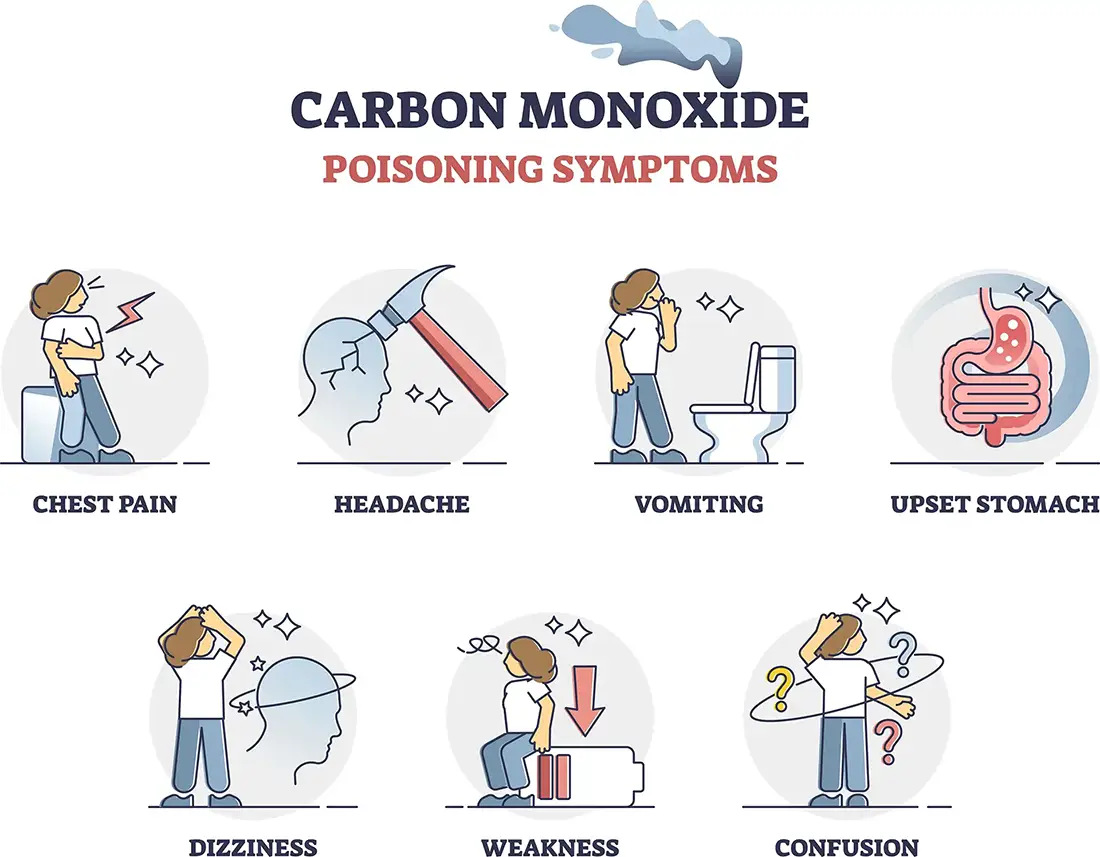

Carbon monoxide (CO) is a colourless and odourless gas, which is highly poisonous and often referred to as the silent killer. It is emitted by vehicle engines together with CO2. Carbon monoxide is produced when combustion reactions are not fully completed, due to insufficient oxygen supply, inefficient combustion, or engine malfunction.

When CO molecules are released into open air, they typically react with oxygen to form

CO2,

following the reaction:

2 CO + O2 → 2 CO2

In this way, in outdoor environments, CO disperses quickly and its concentration drops to

safer

levels. However, in enclosed or poorly ventilated spaces like underground car parks, CO can

accumulate if vehicles or other sources continue to emit it. Without proper airflow, CO may

build up to dangerous levels in parking garages. Furthermore, CO tends to rise and can seep

into

upper levels of buildings, potentially exposing residents and office workers to harmful

concentrations over time.

It is important to note that CO is a much more potent pollutant in terms of

immediate

health

effects, as it interferes with the body's ability to transport oxygen. Breathing

in

CO is

harmful because it binds to red blood cells, preventing them from carrying

oxygen.

This can lead

to symptoms such as headaches, dizziness, nausea, drowsiness, vision problems,

shortness of

breath, and chest or stomach pain. In high concentrations, CO exposure can be

life-threatening.

To reduce CO levels in enclosed areas, fresh air must be supplied to remove the

gas.

For this

reason, many local regulations require CO sensors in parking garages to monitor

air

quality and

activate ventilation when needed.

Where to install the CO sensors?

When installing CO sensors in enclosed spaces like underground parking garages, proper

positioning is key to accurate detection and occupant safety.

Unlike liquefied petroleum gas (LPG), which is heavier than air and tends to settle near the

ground, CO has a similar density to air and disperses evenly throughout the space. For this

reason, CO sensors are typically mounted at breathing height — approximately 1.2 to 1.8

meters

above the floor — where people are most likely to inhale the gas.

To ensure effective monitoring, it’s important to understand the airflow patterns within the garage. Sensors should be placed in areas prone to CO build-up, such as spots with poor ventilation or stagnant air. Avoid installing sensors near walls or in corners, behind pillars or large objects, or in locations where the airflow to the sensor may be obstructed. This can lead to inaccurate readings and delay detection.

In addition, always consult local building codes and regulations, as they may include specific requirements for CO sensor placement in parking facilities. Compliance is not only crucial for safety but also to meet legal standards and avoid potential penalties.

CO2-based ventilation of parking garages

Controlling a ventilation system in parking garages can be done much more efficiently based

on

CO2 measurements. When vehicles with combustion engines are active,

CO2

sensors will be the

first to detect poor air quality, long before the CO sensors notice increased values.

In situations where combustion is not efficient or there's a lack of proper air-to-fuel

ratio,

higher levels of CO can be generated along with other pollutants. However, when CO mixes

with

the air in an underground car park, it will initially further increase CO2

concentrations.

In conclusion, CO2 sensors are essential for monitoring air quality and to guarantee good air quality in underground parking garages. Ventilation systems can be automatically controlled based on real-time CO2 readings to efficiently supply fresh air and remove harmful gases.

Barn Climate

An optimal barn climate is essential in modern livestock farming for animal health, welfare, behaviour, and productivity. Furthermore, it plays a significant role in the safety and comfort of the farmer and the protection of the environment. Climate control in barns involves several aspects, including ventilation, heating, and lighting. The use of fans and heaters, however, results in considerable costs related to energy, investment, and maintenance. In addition, climate control is associated with environmental concerns, such as ammonia and odour emissions, and greenhouse gas output.

Why ventilate?

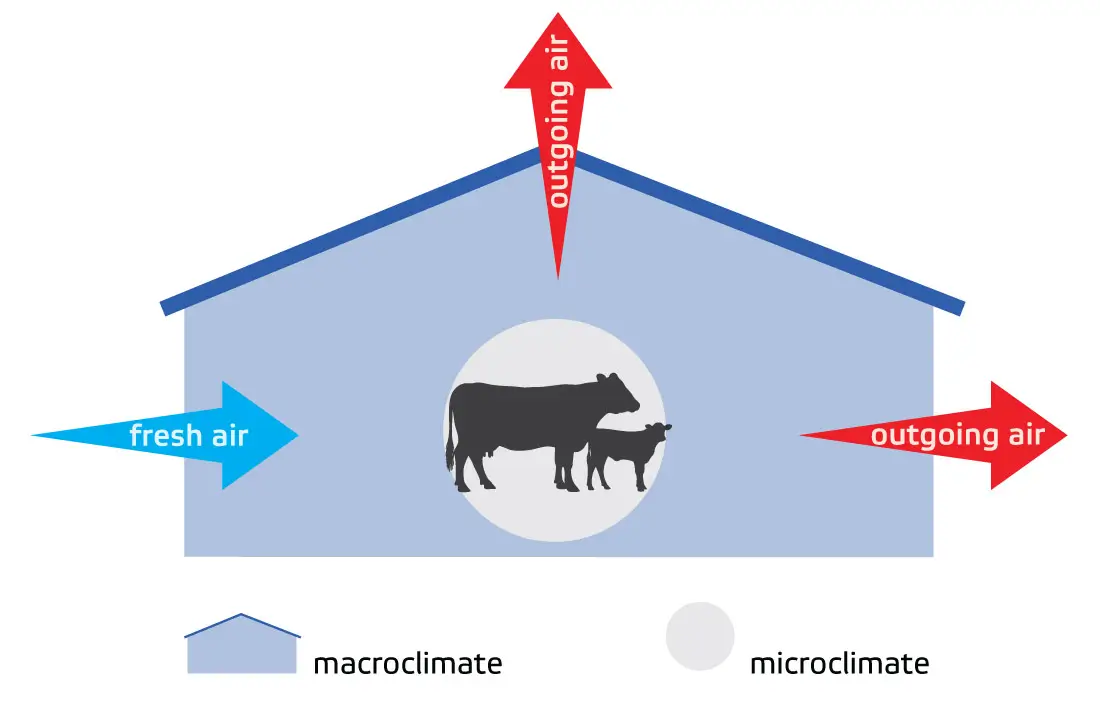

The purpose of ventilation is to refresh the air in the barn. Ideally, the composition of the air inside the barn should approach that of the outside air. However, in practice, this is impossible to achieve due to the continuous production of barn gases, moisture, and heat.

Ventilation helps to remove excessive gases and moisture from the barn, prevent overheating, while continuously supplying fresh air and oxygen into the barn. Optimal ventilation ensures a proper temperature and air quality at the animal level. Drafts or overly fast air movement at the animal level should be avoided.

First of all, let’s make a distinction between the macroclimate and the microclimate. The microclimate refers to the climate at the level of the animals. However, ventilation is usually controlled based on ambient temperature, using a sensor measuring the temperature of the macroclimate rather than the temperature of the microclimate.

The placement of the sensors is, therefore, an important aspect of good climate control. Ideally, the sensors should reflect the microclimate of the animals.

Barn climate parameters

Temperature

Temperature is a crucial parameter of the barn climate. Ventilation aims to maintain the ambient temperature within the thermoneutral zone – or more preferably - within the comfort zone of the animals.

The thermoneutral zone is the ambient temperature range within which an animal can maintain a constant body temperature. However, a good barn climate keeps the ambient temperature within the animals' comfort zone. This is the narrower range within which no behavioural adjustments such as shivering (to produce extra heat), panting (to release heat), or altered lying behaviour are needed to maintain body temperature. Outside the thermoneutral zone, productivity loss is possible due to increased heat production and/or reduced feed intake as a result of heat or cold stress. To get rid of excess heat, animals rely on evaporating moisture that also depends on humidity and air velocity.

The thermoneutral zone and the comfort zone are not fixed values but are variable and depend on several factors:

- Animal species

- Age and weight

- Feed intake

- Climate

Keep in mind that it is primarily the perceived temperature that matters. This is also influenced by other climate parameters, such as relative humidity and air velocity, as well as housing conditions.

Moisture

Moisture is expressed as relative humidity (RH). It is the degree to which the air is saturated with water (vapour) at a specific temperature. The higher the temperature, the more moisture the air can hold. The relative humidity depends on various factors, such as outdoor conditions, barn temperature, respiration and skin respiration of the animals. Furthermore, excretion (manure quality), water intake, and any water spillage also play a role.

Both a high and a low RH are detrimental. With a low relative humidity, a higher barn temperature will be needed to give the animals the same "heat sensation." Furthermore, a low RH irritates the airways and causes respiratory conditions. A high RH, on the other hand, leads to condensation and increased infection pressure, which is harmful to both the barn equipment and the animals.

In barns, a high relative humidity is much more common than a low relative humidity. For pigs, this value should range between 50 and 80 %.

Air velocity

Proper airflow ensures a comfortable environment for animals, prevents heat stress, and maintains good air quality. However, it must be regulated precisely as overventilation wastes energy and can create unnecessary drafts. Air velocity is one of the key elements in climate control and plays a major role in the sensation of temperature. Both too little and too much air movement can lead to problems such as heat stress or drafts, which is a combination of high air velocity and low temperatures. With a high air velocity, animals lose more heat to the environment and perceive more air movement as being colder.

The goal of maximum ventilation is to remove excess heat and ensure that the barn temperature does not rise too high above the target temperature. It also prevents unwanted air currents, or drafts, from affecting the animals.

Barn gases

Barn gases are gases that are commonly found in the air inside livestock barns, generated by animals, manure, feed, and the microbial breakdown of organic material. These gases can affect animal health, worker safety, and the environment if not properly managed through ventilation.

- CO2 (carbon dioxide) is a colourless and odourless gas that

naturally

occurs at concentrations of ± 400 ppm. At normal concentrations, CO2 is not

harmful to

humans or animals. Through the animals' respiration, a significant amount of

CO2

is released

into the barn. In addition, depending on the heating system, a relatively large amount

of

CO2 from the combustion of fuel may also be present.

CO2 is a good indicator of ventilation levels and can be used as a measure for air quality and the set minimum ventilation. In barns, it is legally required that the CO2 concentration remains below 3000 ppm. - NH3 (ammonia) is a harmful, strongly smelling, and irritating

gas

that is formed in the urine and manure of animals from the conversion of undigested

nitrogen. The human nose detects NH3 starting at around 10 ppm. At

concentrations

of 20 to

25 ppm, NH3 can be harmful to both humans and animals.

The NH3 concentration is often used as a measure for barn climate and animal welfare. High NH3 levels may indicate insufficient ventilation, pit ventilation, or excessive fouling of the pens, and promote undesirable behaviours, such as tail and ear biting.

The NH3 concentration should be lower than 20 ppm. It’s quite a challenge to find the right balance between limiting NH3 levels and preventing draft.

Ammonia emission-reducing barn systems have been mandatory since 2003 for new or renovated pig and poultry barns. Additional measures are expected in the future. - H2S (hydrogen sulfide) is a very toxic gas formed during

anaerobic breakdown of manure. It has a low odour threshold of 0.005 to 0.13 ppm and the

characteristic smell of rotten eggs. At concentrations above 100 ppm, the olfactory

organ is

paralysed, and the smell is no longer recognisable by humans, so the danger is no longer

detectable. Concentrations above 1000 ppm can be fatal, causing death within seconds.

H2S can be released during pumping, mixing, or draining manure. The legal limit for H2S in a working environment over 8 hours is 5 ppm in Belgium and only 1.6 ppm in the Netherlands.

- CO (carbon monoxide) is a very dangerous gas that is produced by incomplete combustion. CO can form in the heating system (e.g. a poorly adjusted petroleum burner) when there is insufficient oxygen. By binding to hemoglobin in the blood, oxygen transport is blocked. CO is lethal even at low concentrations of 50 ppm. CO will tend to accumulate near the manure pit, less at animal height.

- CH4 (methane) is a very flammable natural gas that is formed in manure. When it accumulates in the pit, it creates a fire and explosion hazard. Adequate ventilation prevents the accumulation of this gas. Through pit ventilation - incoming fresh air that falls through the slits in the grate and rises again in the manure pit - these gases can reach animal level.

- HCN (hydrogen cyanide) is the most harmful of all barn gases. It is

formed

in the pit from cyanides that naturally occur in plants. HCN binds to hemoglobin in the

blood, causing oxygen deficiency.

Acute exposure can lead to general weakness, headaches, confusion, dizziness, fatigue, panic, shortness of breath, nausea, and vomiting. Due to shortness of breath, unconsciousness can occur, leading to death.

CH4, NH3, and HCN are lighter than air and therefore escape relatively easily from manure pits. In contrast, CO2 and H2S are heavier than air and thus do not escape as easily from the manure pit and tend to 'linger' more in the manure pits.

Dust

Dust is always present in pig and poultry barns. It is usually of organic origin,

from feathers, skin flakes, feed, faeces, bedding,… and carries bacteria and viruses.

The dust concentration and the size of dust particles determine their level of

harm: the

smaller

the particles, the more harmful they are to both humans and animals. Especially

particles

smaller than 10 µm are the most harmful; they penetrate deeply into the lungs

causing

serious

respiratory diseases. Wearing a dust mask in the barn is advisable. The dust concentration in the barn should be lower than 2.4 mg/m³, with

concentrations in

practice varying between 1 and 10 mg/m³.

Light

Light is essential for animal welfare, health, productivity, and legal compliance. It must be

adapted to the species, age, and behaviour of the animals to ensure optimal living

conditions.

Light intensity influences hormone production and consequently also feeding behaviour,

growth

rates, egg production and activity levels. Animals have natural preferences for certain

light

levels and need enough light to see their surroundings, pen mates, and feed and water. Too

much

light, on the other hand, can increase stress. Regulations mandate minimum light intensities

and

periods of light and recent buildings must include natural light openings. Light intensity

can

be measured with a lux meter.

Barn sensors

A barn is far from an ideal environment for sensors. Dust, moisture, and ammonia can be very harmful to a sensor that is not properly shielded. An IP classification of at least IP56 - splash-proof and dust-tight – is therefore required.

It is usually recommended to remove the sensors during a thorough cleaning of the barn. The ease with which the sensor can be removed and reinstalled can therefore play an important role in the sensor selection. A good system should ensure that all open connections can be shielded by flaps or screw caps after removing the sensor.

Greenhouse

Greenhouses play a vital role in modern agriculture, enabling year-round cultivation by creating a protected and controlled environment for plant growth. One of the most critical aspects of greenhouse management is climate control. Maintaining the right temperature, humidity, and air composition directly influences crop quality, growth rates, and overall yield.

What is a greenhouse?

A greenhouse is a structure generally made of transparent materials like glass or plastic, designed to create a controlled environment for growing plants. It allows sunlight to enter and warm the air and soil inside, while protecting plants from pests, wind, rain, and extreme outdoor temperatures.

The main purpose of a greenhouse is to extend the growing season and provide

optimal

and stable

conditions for plant growth by controlling temperature, humidity, light, and

CO2 levels. Shading

and

heating or cooling systems can be added to maintain a stable climate.

Greenhouses are widely used in horticulture and agriculture to grow vegetables,

flowers, fruits,

and

ornamental plants more efficiently and with higher yields, regardless of outside

weather

conditions.

Greenhouse ventilation: natural or controlled

Ventilation is essential in greenhouses to create a healthy, productive environment for plants. It regulates temperature, humidity, and CO2 levels, preventing problems like overheating, mould, diseases, or excessive moisture. Greenhouse ventilation can be achieved through natural or controlled systems.

Natural ventilation relies on roof vents, side vents, and louvers to allow warm air to rise and escape while cooler air enters passively. This passive approach is simple and energy-efficient but may not be sufficient under extreme weather conditions or in larger greenhouses.

Controlled ventilation uses fans, sensors, circulation systems, and automated controls to actively manage airflow, temperature, humidity, and CO2 levels. Exhaust fans remove hot, stagnant air, while circulation fans distribute air evenly to prevent uneven heat or moisture build-up. Modern control systems can automatically operate fans, vents, or dampers based on set parameters, ensuring stable year-round conditions that support higher yields and healthier crops. Although it requires more investment and energy than natural ventilation, it offers greater precision, reliability, and adaptability.

Greenhouse climate parameters

Maintaining the right climate in a greenhouse depends on closely monitoring and controlling several key parameters:

Temperature

Maintaining the right temperature is crucial for plant

metabolism and growth,

including overall health, flowering, and fruiting. The ideal range varies by crop, but is

generally between 18–30 °C.

Temperature is controlled using heating, cooling, shading, and ventilation systems, which

prevent overheating during the day and excessive cooling at night.

Relative humidity

Humidity levels in a greenhouse affect plant transpiration (water loss through leaves), disease susceptibility, and overall vitality. Too high humidity can lead to fungal diseases, while too little can cause plant stress. Optimal humidity usually ranges between 50–80%, depending on plant type and growth stage. Humidity is managed through misting, dehumidifiers, and ventilation, which remove excess moisture and keep conditions within the optimal range.

Carbon dioxide

Adequate CO2 levels are essential

for photosynthesis and

biomass production. In barns, CO2 must be exchanged with fresh air to keep

concentrations as low

as possible, for both animal and human safety. In greenhouses, by contrast, CO2

must

be supplied

to support plant development. Plants perform optimally when CO2 levels are

maintained

between

400 and 1000 ppm.

Sentera sensors can measure concentrations up to 10 000 ppm. Enrichment systems and steady

airflow help provide the right CO2 concentrations to optimise growth conditions.

Light

Light is the energy source for photosynthesis, which powers plant growth.

Both the amount (intensity) and type (spectrum) of light matter. Most crops need 12–16 hours

of

light daily. Crops like mushrooms, on the other hand, prefer low(er) light levels.

Monitoring ambient light and the use of grow lights and shade cloths ensure optimal

exposure.

Soil moisture

Roots require both water and nutrients to support growth, so

maintaining the right soil moisture is vital. If the soil is too dry, plants’ ability to

absorb

nutrients is limited, which stunts their growth. However, if the soil is too wet, it becomes

a

breeding ground for harmful bacteria and fungi.

Soil sensors and irrigation systems help maintain the right balance, preventing drought

stress

and overwatering while supporting healthy root function.

Summary table

| Parameter | Impact | Control |

|---|---|---|

| Temperature | Metabolism and growth | Heating, cooling, shading, ventilation |

| Humidity | Transpiration and disease | Misting, dehumidifiers, ventilation |

| CO2 levels | Photosynthesis and biomass production | Enrichment systems, airflow |

| Light | Photosynthesis | Grow lights, shade cloths |

| Soil moisture | Root function and nutrient uptake | Irrigation, soil sensors |

Airflow management

Ventilation removes excess heat, regulates humidity, and supplies fresh CO2 for photosynthesis. It also helps prevent plant diseases by promoting air circulation. Proper distribution of air within the greenhouse is essential to ensure all plants experience the same environmental conditions. Circulation fans and forced air systems help even out temperature and humidity, prevent stagnation, and support an optimal climate.

Sentera sensors and controllers for agriculture and horticulture

Monitoring and maintaining environmental conditions are vital for optimising ventilation strategies in agriculture and horticulture. Sentera offers advanced sensors that measure CO2, soil moisture, humidity, light, and temperature. These sensors can directly control fans, vents, or irrigation systems, prevent overwatering, and continuously log environmental data.

Sentera sensors are specifically optimised for agricultural and horticultural applications. Their measuring ranges are wide, which makes them suitable for various uses, and their electronics are treated with a special coating to enhance corrosion resistance.

With Modbus and SenteraWeb connectivity, both small and large-scale agricultural setups can integrate smart control, remote monitoring, alarms, and preventative maintenance. Modbus networks can be up to 1000 meters long and manage up to 247 devices, with the option to extend even further using repeaters. This allows for demand-based ventilation and seamless integration into a comprehensive greenhouse management system.

SenteraWeb further enhances the value of Sentera sensors by enabling detailed data logging and automated alerts when parameters fall outside desired levels.

In conclusion, intelligent monitoring, combined with natural and controlled ventilation, allows greenhouses to maintain optimal growth conditions, increase productivity, and operate efficiently and sustainably.